Gang Saw

Gang Saw

Gang Saw

PROGRAMMING AND MANAGEMENT SYSTEM

Gang Saw Technical specification

مشخصات فنی اره سنگ

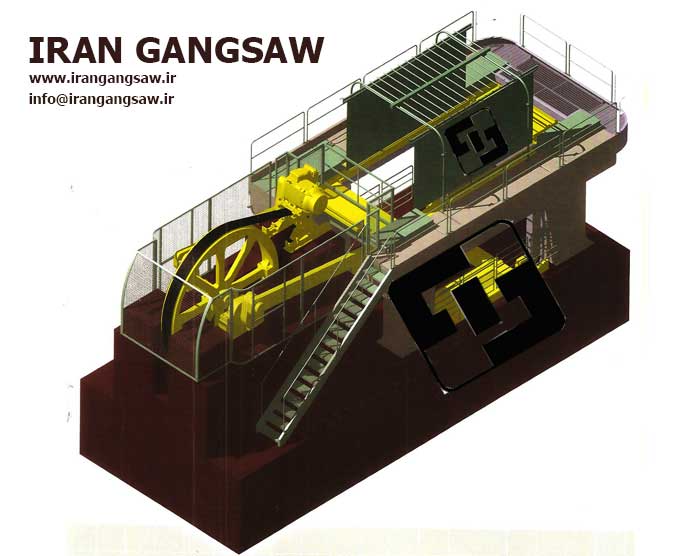

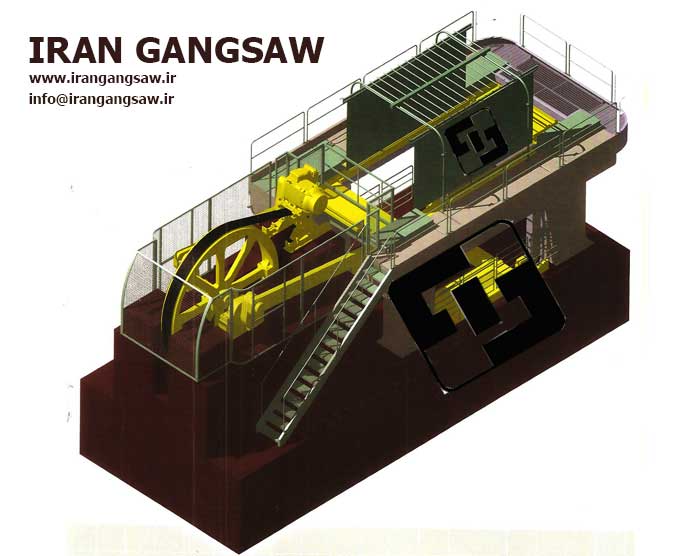

ذخایر محدود و تجدیدناپذیرند و برای استفاده هر چه بیشتر از این منابع خدادادی،کاهش هزینهها، فزایش راندمان و کاهش ضایعات سنگ استفاده از ماشینآلات روز دنیا و همگام شدن با فناوریهای جدید فرآوری سنگهای ساختمانی و تزئینی امری اجتنابناپذیر است. در این خصوص به معرفی کلی اره گروههای برش کوپ سنگ و تولید اسلب میپردازیم. یکی از ماشینآلات کاربردی در چرخه فرآوری سنگهای ساختمانی و نما و تهیه اسلبهای بزرگ، اره گروههای چند تیغهای هستند که جزو جدیدترین تکنولوژیهای مورد استفاده در صنعت سنگ است. اجزای اصلی اره گروهها: - چهار چوب فولادی - چرخ لنگر - بازوی انتقال حرکت - میز بالابر کوپ - موتور اصلی - فریم تیغهها در این دستگاه یک چهارچوب بزرگ شامل چند تیغه فولادی که در فواصل معین از یکدیگر قرار گرفته و محکم شدهاند، وجود دارد. سیستم کار اره گروهها بهطور کلی مشتمل بر حرکت تیغههای فولادی،حرکت کوپ به سمت بالا، برش کوپ سنگ تا انتها و تبدیل کوپ سنگ به اسلب است. اره گروهها دارای تعداد تیغههای متفاوت و به صورت عمومی 80 تا 100 تیغه دارند. قطر اسلب تولید شده مورد نظر تعیینکننده فاصله تیغههای اره از یکدیگر هستند. محل عکسها

Gang Saw bridge Features

ویژگی اره سنگبری

The characteristic feature of this type of gang saw is the frame’s movement of the retaining blades onto the hydrostatic linear guides, which has the following advantages: *Flywheel with a diameter of 3.5 m and a weight of 8500 kg to create uniform motion and provide the necessary energy for cutting *Shatton made of casting steel, resistant to impact and machined with the highest accuracy *Making guide bushes made of phosphor bronze anti-abrasion *The main shaft of the device is made of forged steel with high resistance to dynamic loads *Perform ultrasonic testing on the main shaft to ensure its surface quality and prevent the growth of fine cracks after turning *Accurate calculation, analysis and engineering selection of all parts of the machine in order to have enough strength and long life *The highest precision in machining parts and structures of the device for its high performance and long service life *Three-layer epoxy paint coating with paint spray equipment *Purchase of standard parts including bearings, belts, bearings and …from reputable European brands. *PLC Power Switch with the most comprehensive control equipment and HMI display *Startup of the engine as software starter to prevent demand plant increase, reduce power consumption at startup and protect the main engine *The ability to enter the stone block from the front and side of the device *Automatic lubrication of the machine’s main screws and fixed and pressure sliders *Delivery of two trolleys with the device انواع کلی اره گروهها: بر حسب نوع سنگ مورد فرآوری، دو نوع اصلی اره گروه کاربرد دارد و عملکرد عملیاتی کلیه مدلهای ارایه شده توسط تولیدکنندگان به این دو نوع برمیگردد. 1) اره گروه برش گرانیت و سنگهای آذرین (سنگهای سخت ) 2) اره گروه برش مرمریت و سنگهای آهکی (سنگهای نرم ) اولین نوع اره گروه برای برش کوپهای گرانیت و سنگهای مرتبط مناسب است. این نوع اره دارای تیغههای فولادی بدون ابزارهای اضافی و نوعی حرکت پاندولی به هنگام برش است. حرکت پاندولی بندرت به صورت مستقیم صورت میگیرد. برش در این اره گروهها در نتیجه عمل مورد نظر از آب و آهک و ساچمههای چدنی یا فولادی تشکیل شده است و به طور پیوسته از بالا بین تیغهها و کوپ ریخته میشود. عامل ایجاد حرکت پاندولی تیغهها آن است که کنراد یا حلقه مفصلی جفتکننده در این ارهها بر خلاف ارههای مرمریت بر مستقیماً به دسته نگهدارنده تیغه متصل نشده است بلکه از طریق یک قطعه واسطه به آن وصل شده و موجب حرکت پاندولی شکل میگیرد. در نیجه تیغهها علاوه بر عمل برشی خود یک ضربه برخورد شدید نیز بر کوپ وارد میکنند که به فرآیند برش بسیار کمک میکند. چنین نوع حرکتی امکان نصب قطعات الماس برروی تیغهها را سلب میکند و در نتیجه برش گرانیت توسط تیغههای فولادی صورت میگیرد. عملیات اره کردن گرانیت پیچیدهتر از مرمریت است و میزان سرمایهگذاری آن نیز قابل توجه است. این ماشینها نیازمند زیربنایی دقیق هستند و با توجه به سرمایهگذاری قابل توجه این ماشینها باید بیشتر اوقات سال یعنی حدود 330 روز در سال و حداقل 2 شیفت در روز کار کنند تا هزینههای تولید بالا نرود. تعداد پارامترهایی که باید در اره گروههای گرانیت بر کنترل شوند عبارتند از: چگالی- ویسکوزیه – اندازه دانههای دوغاب، کشش اعمال شده بر تیغه، سیستمهای هیدرولیک و ... هرگونه وقفه در تولید بلافاصله هزینههای تولید را به صورت چشمگیری تحت تأثیر خود قرار میدهد. دومین نوع اره گروه برای برش مرمریت و سنگهای مرتبط مانند تراورتن مناسب است. در این دستگاه تیغهها در یک خط مستقیم و در مسیر برشی رو به پایین حرکت میکنند. تیغهها در لبههای برنده خود قطعات الماس دارند که با حرکت تیغهها به سمت جلو و عقب باعث سایش و برش کوپ میشوند. به هنگام کار تیغهها، میزان آب کافی به آنها باعث خنک شدن تیغهها و نیز شسته شدن خرده سنگهای ناشی از برش میشود. اره گروههای مرمریت شامل مدلهای متفاوتی هستند در بعضی مدلها کوپ ثابت است و تیغهها از میان کوپ ثابت به سمت پایین حرکت میکنند در مدلهای دیگر کوپ به سمت بالا فشار داده میشود و برخی مدلها مجموعهای از تیغههای عمودی دارند. سرعت برش رو به پایین از کمتر از یک سانتی متر در ساعت تا چندین سانتیمتر در ساعت برای گرانیتها و دهها سانتیمتر برای مرمریتها متغیر است. بسته به حجم کوپها میتوان یک یا چند کوپ را بروی هر اره قرار داد.

Gang Saw bridge

دستگاه اره سنگبری

The Gang Saw has been designed for cutting Marble. This machine has excellent performance in cutting speed and quality due to the movement of the frame supporting the blades on four linear guides with hydro static lubrication. ویژگیهای اره گروهها 1) دقت در برش: با توجه به ساختار فولادی ثباتی فوقالعاده را برای سیستم تضمین میکند. همچنین بغل بندهای موجود کوپ را در حین عملیات برش به خوبی نگهداری میکند که این خود موجب افزایش دقت در عملیات برش میشود. 2) ظرفیت بسیار بالا در استقرار کوپهای سنگی برروی اره: عرض مفید بارگذاری 2 متر برای 80 عدد تیغه است. 3) تولید 16 متر مربع سنگ برش خورده از یک تن سنگ 4) کاهش 15 درصدی ضایعات سنگ به لحاظ ایجاد سطوح و ابعاد یک پارچه سنگ در تولید اسلب 5) توان تولید اسلب باابعاد 5/3 – 3 × 2 – 8/1 متر ( ابعاد اسلب تولیدی بستگی به ابعاد کوپ دارد ) 6) یک میلیمتر ضخامت مورد نیاز جهت کالیبر وساب سنگ 7) میزان مصرف برق کمتر در مقایسه با دیگر ماشینآلات برش کوپ 8) برش 50 متر در هر ساعت برای سنگهای نرم و 40 متر مربع در ساعت برای سنگهای سخت 9) کاهش تقریبی 50 درصدی در گل شدگی سنگ 10) توان تولید اسلب با ضخامت 15 میلیمتر (به ندرت کمتر از 15 میلیمتر) الی 100-80 میلیمتر 11) سرعت بالا وکار منظم

بررسی سیستمهای برش ارهگروهها (GANG SAW) با نگاهی به ویژگیهای

CNC BRIDGE SAW WITH ROTATING HEAD FOR MARBLE, GRANITE, ENGINEERED STONE AND CERAMIC SMART-CUT 550 is a cnc bridge saw cutting centre with interpolated axes, equipped with rotating head and fixed work bench, designed to perform multiple machining operations which would otherwise require several machines, such as: cutting of slabs, shaping and dishing out of small blocks of marble, granite, sandstone, limestone and stone, engraving of inscriptions, drilling, etc. using either the diamond disc or the drills.

iran gangsaw اره سنگبری ایران

Gang Saw

- Latest generation SIEMENS 840 SL digital NC. - High-speed and high-precision movements along axes X, Y, Z thanks to brushless digital motors with absolute encoder. - Spindle carriage made of cast-iron to ensure rigidity and vibration damping. - The beam is moved by a precision rack and pinion assembly, driven by brushless digital motor. - The spindle carriage is moved by recirculating roller runner blocks, driven by brushless digital motor that ensures the required precision and rigidity. - The spindle is moved vertically by a ball screw/preloaded nut assembly on recirculating roller guides, driven by digital brushless motor. - All guides are protected and greased. - Twist head with a ± 190° rotation on axis “C” and 0° to 90° rotation on axis “A”. - The disc inclination is motorized and can be programmed in any position between 0° and 90°, with possibility of making step-cutting (with continuous head rotation). - User-friendly software displayed on colour touch-screen, which is mounted on the control panel; joysticks for moving the various working axes easily. - Laser tracer displaying the cutting path.

smart-cut-snc-550-bridge-saw

On request, the work bench can be equipped with a tilting top; in the S/NC 550B version, the bench is equipped with a motorized conveyor belt so as to automate the loading and unloading operations. STRUCTURAL AND FUNCTIONAL FEATURES

PROGRAMMING AND MANAGEMENT SYSTEM

Cras volutpat tempus

smart-cut-snc-550-bridge-saw - The machine is managed and programmed from a colour touch-screen installed on a practical, hanging control console, which is easy to handle and can be rotated. - The machine is controlled from the CNC PC with Windows operating system. - The management and operational software use the Windows environment to its full potential, are extremely user-friendly and can be easily interfaced with the user’s system. - The colour touch-screen makes the machine programming easy and fast. - All electric and electronic components are from world’s leading producers so as to ensure that spare parts can be easily sourced in the event of a system failure, and technical assistance is available at a world level. - The machine is equipped with a simple portable button panel to control its major functions in order to operate it in the manual mode and make easier some operations to be carried out within the working area.

Cras volutpat tempus nunc eu neque odio non dui. Morbi massa quis dolor. Donec porttitor.

Tmec bridge saw Smart-Cut 550 at work

Tmec bridge saw Smart-Cut with twist head is the ideal machine for marble fab shops since it meets a wide variety of requirements, such as:

Smart-Cut S/NC - Bridge saw cnc with rotating head and 5 interpolated axis

SMART-CUT S/NC 550 is a CNC cutting and profiling machining centre. It is equipped with a rotating head and fixed worktable and is designed to accomplish multiple machining operations which would otherwise require several different machines or other time consuming manual interventions requiring multiple movements of the material.